CUSTOM PLASTIC PIPE WELDING SOLUTIONS

RIYANG team of custom welding machine experts have more than 15years experience of advanced welding design, development and programming knowledge. We are unmatched in creating custom welding solutions for general industry customers in plastic pipe welding applications.

From the perspective of customers, our team pursues the rationality of product design, the safety of product use, and the reliability of products. We thrive when solving complex plastic pipe welding challenges.

From the perspective of customers, our team pursues the rationality of product design, the safety of product use, and the reliability of products. We thrive when solving complex plastic pipe welding challenges.

OUR CUSTOMER-CENTRIC PROCESS

Our custom plastic pipe welding equipment process starts with listening to your needs. We will take into account the custom equipment applications, the materials that need to be welded, and what target to be achieved. We will collaborate closely with you on every step. We will keep you informed of the progress of each customization part. At RIYANG, our goal is to deliver one machine to you that truly addresses your needs and continuously create value. Your success is also our success.

Process

1 Early communication

2 Needs Assessment & Design Concept

3 Design

4 Parts Processing

5 Assembly

6 Testing and Debugging

7 Deliver (install and start-up)

After delivery, we’re here to provide you with any training,

support and service you need.

CUSTOM PLASTIC PIPE WELDNG SOLUTION EXAMPLES

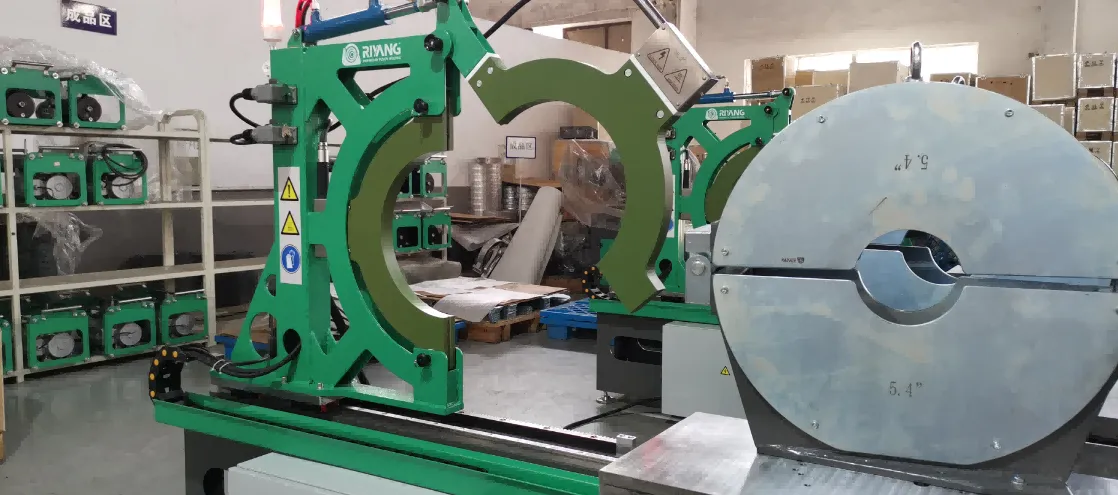

WORKSHOP WELDING

MACHINE FOR INSULATION

PIPE 5.4”-18.2”

AUTOMATIC MANIFOLD WELDING MACHINE

TRAILER BUTT FUSION

MACHINE in accordance with

ASTM F2620 high pressure

welding 4” - 14” IPS, 110mm-

355mm